Right-sized ducts are critical for operational efficiency and constant airflow of HVAC systems. Be it for a new system or for an upgrade on an existing system, having the correct size ducts prevents energy drain, avoids undue system wear, and improves system efficiency. Duct sizers are a great aid for determining the airflow, pressure losses, and type of duct material duct requirements so that all factors are catered for efficiently.

This guide aims to provide all the steps needed to accurately size flexible ducts using duct sizers. Moreover, critical issues like flexible duct flow switches, duct gauge thickness, duct flow switches, duct gauge thickness, and the ASHRAE duct fitting database will be discussed.

What is a Duct Sizer?

A duct sizer is a device that finds the optimal dimensions of ducts needed for an HVAC system. It analyzes the airflow (in CFM), pressure loss, and other system specifics. Getting the right size for flexible ducts is very important for system performance. Correct sizing improves system efficiency. Optimal duct sizing reduces energy consumption and mechanical strain, increases system longevity, and enhances operational efficiency. It also averts system strain, balances temperature control, and prevents operational blockages, sustaining seamless airflow. Ultimately, accurate sizing improves efficiency and durability of the HVAC system.

Why Proper Duct Sizing is Essential

If ducts are undersized, it can lead to restricted airflow, increased energy usage, and excessive strain on the HVAC system. On the other hand, oversized ducts can create turbulence, resulting in inefficient airflow and wasted energy. Therefore, selecting the right duct size for each application is crucial to ensuring the system operates at peak efficiency.

How to Use a Duct Sizer to Properly Size Flexible Ducts

Determine Airflow Requirements

Begin by calculating the airflow required for the system. This includes looking at the size of the space, the number of air vents, and how much airflow is needed (measured in CFM). Larger rooms and higher HVAC demands typically require greater airflow. Once you have this figure, input it into the duct sizer to start determining the appropriate duct size.

Choose the Right Duct Material

The type of material used for the duct also the most commonly used galvanized steel, aluminum, and flexible ducts affects the consideration of the duct size. Unlike other types of Flexible ducts possess ease of use during installation and are adaptable within small spaces. These flexible ducts are not as good as rigid ducting as they possess high friction loss which makes duct sizing as the airflow will be impacted.

While sizing flexible ducts, various suggestions come into play. These include the need for the ducts to be the right dimensions in order to avoid excessive pressure loss or air turbulence. The flexible duct connectors also have to be covered as they also play the role of adding friction into the system.

Consider Duct Gauge Thickness

As with all other systems, a duct system consists of parts whose thickness and materials vary. The duct gauge thickness evaluates the separate parts of a duct and, as the name describes, the thickness of material of a duct. More rigid materials might be more durable, hence affecting the airflow. As a side note, rigid ducts, unlike flexible ducts which have thinner materials, have a higher gauge thickness because they are more durable. Gauge thickness matters in controlling airflow in addition to the structure of the duct, particularly in high pressure systems..

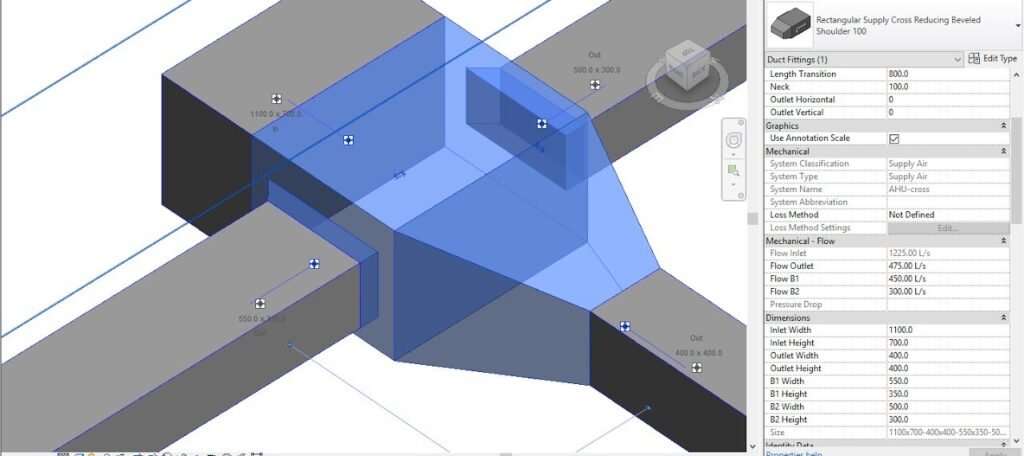

Utilize the ASHRAE Duct Fitting Database

The ASHRAE duct fitting database is an excellent resource for calculating the friction loss in ducts. It provides data on how various fittings (such as elbows, tees, and transitions) affect airflow. If you’re using flexible ducts, it’s essential to refer to the ASHRAE database, as flexible ducts typically have higher friction losses due to their material flexibility and connection fittings. This helps you make adjustments for accurate sizing and ensures your ductwork meets industry standards.

Ensure Proper Duct Flow Switch Installation

Duct flow switches are devices installed to monitor airflow within the system. They help ensure that air is moving correctly through the ducts, preventing issues like blockages or low airflow. These switches are particularly important when using flexible ducts, as these ducts are more susceptible to kinks or blockages due to their design. Ensure that duct flow switches are positioned properly to maintain constant airflow monitoring and help identify any potential issues early.

Finalizing the Duct Size with a Duct Sizer

Once you’ve inputted all the required data into your duct sizer, the tool will provide you with the correct duct size. For flexible ducts, ensure that all the friction loss, gauge thickness, and flexible duct connectors are factored into the sizing calculation. The sizer will recommend the optimal diameter or area that will allow sufficient airflow while minimizing energy loss and pressure buildup.

Common Mistakes When Sizing Flexible Ducts

Not Accounting for Friction Loss in Flexible Ducts:

Compared to rigid ducts, flexible ducts have a friction loss which is comparatively higher due to their design and material composition. Increased friction loss is likely to have a profound effect on airflow and efficiency of the system. When using a duct sizer, proper adjustment of calculations is critical to maintain proper airflow because ducts may not be the correct size. Overlooking friction loss may result in smaller ducts being fitted, which in turn, causes inadequate airflow, increased energy consumption, and degraded performance of the system as a whole. Maximum performance of a system, particularly a flexible duct system, requires that friction losses, particularly in a system using flexible ducts, need to be calculated and integrated in the design.

Ignoring Duct Material and Gauge Thickness:

The airflow dynamics and performance efficiency of the system is heavily reliant on the specific materials and the gauge thickness of the duct. Varied materials, for instance, galvanized steel or flexible ducts, exhibit differing levels of resistance to airflow. Moreover, the thickness of the duct material affects the structural integrity alongside the efficiency of the airflow. Balance maintenance between airflow and pressure in flexible ducts is more stringent, requiring careful calibration. Failure to account for these aspects can destabilize airflow and waste energy, thus HVAC system performance is compromised.

Underestimating the Impact of Duct Connectors:

While frequently ignored, flexible duct connectors have a friction and resistance effect in a system. These connectors are needed for transitional changes between ducts and system parts. However, if proper consideration is not given for sizing, they can cause too much restriction, resulting in improperly sized ducts. This can lead to undersized ducts that are incapable of delivering the needed airflow which in turn diminishes the performance of the system. To avoid this scenario, always take into account the additional resistance posed by duct connectors.

Not Using ASHRAE Guidelines:

The ASHRAE duct fitting database gives critical information regarding the friction losses associated with elbows, tees, and any other transitions. It is important to refer to this database while calculating friction losses, as failing to do so would lead to friction losses being miscalculated and result in an ineffective and inefficient system that shall deviate from the set benchmarks. ASHRAE duct fitting databases are essential to uphold consistency in airflow and assure that every fitting is considered while calculating duct sizes. Ignoring these guidelines would result in inefficient and non-optimized systems lacking performance, which would cause adverse ramifications operationally in the long-term.

Why Choose an Airlutions’s Engineer for Your Duct Sizer Needs?

Selecting the right provider for flexible duct sizing is crucial for the efficiency of your HVAC system. Airlution Engineers, as skilled HVAC engineers, have a broad experience understanding the exact requirements of a residential or commercial duct system, as they precisely tailor the duct sizing for the needs of the HVAC system. Ensuring optimal airflow and energy efficiency, their methodology also incorporates duct gauge thickness, duct flow switches, and flexible duct connectors. Airlution Engineers apply industry-leading techniques, for example ASHRAE duct fitting database, to make sure that your ductwork is designed to the highest standards in efficiency, durability, and performance. Relying on Airlution Engineers for your HVAC system design guarantees an energy-efficient system that reduces mechanical strain, improves operational reliability and provides superior, consistent air distribution for years to come.

Conclusion

Proper sizing flexible ducts is critical for the efficiency and effectiveness of an HVAC system. As an Airlutions representative and HVAC specialist, I always recommend that system width gauge, duct gauge and thickness, flexible duct connectors, and the ASHRAE duct fitting database components are incorporated into Airlutions’ procedures so that the system functions seamlessly and smoothly. Every single flexible and rigid duct system should be precisely sized with a duct sizer to ensure optimal airflow, reduced energy expenditure, and an extended HVAC lifespan. I ensure that best practices are followed for maximum system optimization, for example, the duct sizer is used with care and friction losses, gauge, material, and fittings are included, and best practices are followed. This HVAC methodology leads to an optimized duct system tailored for the HVAC requirements of the customer.