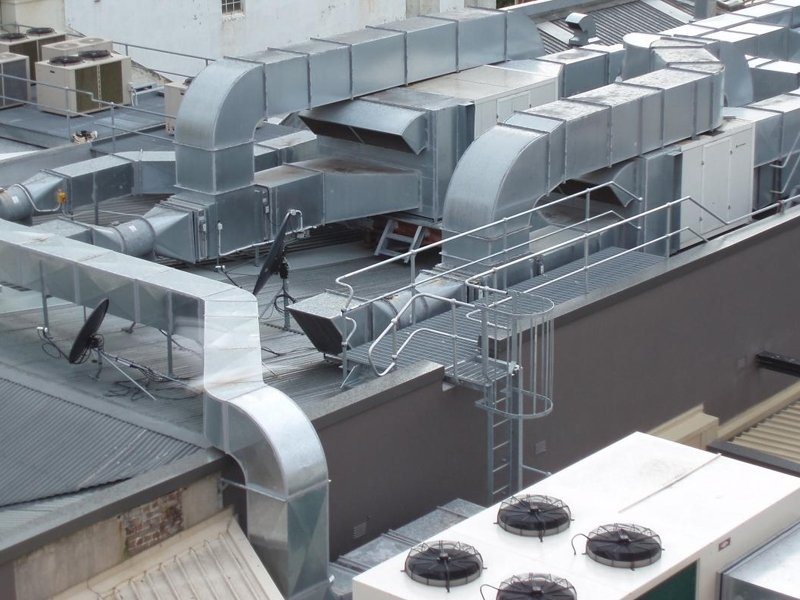

The correct choice of your duct material is absolutely key for maximising the efficiency, longevity and cost effectiveness of your HVAC (Heating, Ventilating and Air Conditioning) project. There are so many ducting options available in the market, that it’s necessary to compare each material in a way that allows for its durability, costs, energy performance, type of installation, etc. This will guide you through the list of well-known duct materials, such as galvanized steel duct reducers, textile ducts, flexible ducting hoses, duct flanges, and such. Now let’s compare the pros and cons of each of these materials so that you can make an informed choice for your HVAC project.

Understanding Duct Materials

Duct material is available in a variety of different styles, including metal and flexible fabric, to serve different applications based on project needs. Let’s explore these materials in-depth.

Galvanized Steel Ducting

Overview: Galvanized Duct reducer isn’t used as much because of the difficulty in forming things with it. This type of duct is made from steel sheets coated with a layer of zinc, making it resistant to rust..

Durability: These ducts are very long lasting. The zinc finish provides resistance to corrosion, and is an indication of the gauge of the steel, which is a standard gauge. It’s strong and can resist corrosion, rust, and physical damage.

Cost: This can be a pricey material. Galvanized steel ducting may cost anywhere from $6 to $12 to $13 per linear foot depending on the metal thickness and size of duct used. Its initial cost is higher, but in the long run, it can be more affordable because it lasts longer and requires little maintenance.

Energy Performance: Galvanized steel is a stiff metal sheet and though the model is very small, galvanized duct reducer air flow resistance. Installed and insulated properly, it is energy efficient and can reduce energy loss. But it does conduct heat, so it needs to be insulated well or energy may be lost.

Best For:

- Indeed, such large scale commercial and industrial HVAC systems

- Applications where longevity and performance are of concern

- Negative aspects[ Areas of concern regarding corrosion

Fabric Ducting

Overview: Fabric ducting (sometimes referred to as textile ducts) are produced from high-strength fabrics and are suitable for Residential and light commercial applications. These pipes are flexible, lightweight, and very easy to install. This product is commonly used in all sorts of soft, aesthetic duct applications.

Durability: Fabric duct is durable, but not as durable as it is, for example, galvanised steel. Fabric can also wear out with moisture or abrasive air-flow and cloth material in humid or temperature varying regions. But which are rust-resistant and won’t corrode.

Cost: Fabric ducting is one of the most cost-effective options on the market. The average price per foot typically ranges from $3 to $6, making it an excellent choice for homeowners or smaller HVAC projects on a budget. Installation costs are also lower due to their lightweight nature and easy handling.

Energy Performance: Fabric ducts can deliver uniform air dispersion, which can contribute to energy savings. Though light and bendable, they are commonly used in systems requiring the distribution of air. However, the fabric ducts may be less energy efficient in a larger, higher-powered unit because they tend to leak air if not adequately sealed.

Best For:

- Residential HVAC systems

- Less commercial or retail accommodations

- Shoestring budget games needing to look good

Flexible Ducting Hose

Overview: Flexible ducting hoses are a very popular choice for many because of their ease of installation. They are usually constructed with aluminum, PVC, and steel, which makes them structurally adaptable and strong. It is the staple material utilized in construction applications for both the residential and commercial building industries.

Durability: Flexible duct hoses are not uber-long-living, though they still last longer than their rigid counterparts like galvanized steel. The materials, over time, can degrade, particularly when subject to extreme temperatures or moisture. They also tend to be more vulnerable to damage from physical contact.

Cost: Flexible ducts cost less than any other type of ducting. They are sold in increments of 25’ and the price per +/- foot is between $2 and $5, perfect for small scale or home HVAC ducting projects. But the affordability brings some sacrifices with regard to long-term durability and energy performance.

Energy Performance: A disadvantage of flexible duct hoses is that they will lower the efficiency of airflow. The inner walls of flexible ducts introduce more friction, which sometimes results in greater energy consumption. Leaks in flexible ducts, if not properly sealed, can equal significant loss of air and decreased energy efficiency. Insulated flexible ducts can be found, but they are still less efficient than a rigid duct such as galvanized steel.

Best For:

- Household HVAC installs or small jobs

- If you are a contractor or a home owner and you have a renovation project with flexibility and easy to install.

- Regions where budget is the main issue

Aluminum Ducting

Description: Aluminum duct is a lightweight and corrosion-resistant option. It’s a frequent choice for residential and light commercial applications. Aluminum is a filamentous material that has a variety of properties including corrosion resistance and weathering performance.

Durability: Aluminum is a light material, which makes it easy to handle and work with. But they are also weaker than galvanized steel and more susceptible to physical deformation. Aluminum doesn’t rust, making it perfect for wet or humid areas.

Cost: The cost of aluminum duct piping is generally $4 to $9 per foot. It’s less expensive than galvanized steel, but still provides decent durability and performance. The price may fluctuate depending on the grade and quality of aluminum used.

Energy Performance: Energy Efficiency Aluminum is an excellent heat conductor, which can cause your windows to contribute to energy loss if not sufficiently insulated. Insulated aluminum duct can help reduce the problem, but it is less effective than galvanized steel for preventing energy loss.

Best For:

- Residential HVAC systems

- Wet or damp areas

- Smaller commercial spaces or buildings

Duct Flanges and Duct Works

Overview: Duct Flanges is an equipment used to seal and attach duct works to the duct devices so that air can go through the duct work without leaking. Duct works meanwhile refers to the entirety of ducts, flanges, and the like which comprise the ventilation system.

Durability: Generally ducting is made of galvanized steel and aluminum which provides good durability. But they do need to be installed correctly to work. Leaky flanges or inadequate ducting can result in leaks, which compromise system performance.

Cost: Flanges and duct works are generally sold with the total HVAC unit and so pricing is done likewise. This will be influenced by which parts are needed for a particular system and how large it is. But, these parts are often cheaper than material that your main ducts are made of.

Energy Performance: Properly installed flanges and duct works can help increase overall performance of the HVAC by avoiding air escape. When the ducts are well sealed, energy loss is kept to a minimum and the system functions at peak energy efficiency.

Best For:

- Any HVAC system that air ducts that need to be well sealed

- Commercial and home systems that need efficient installation and energy savings

Choosing the Right Duct Material for Your HVAC Project

Now that we’ve evaluated the pros and cons of each duct material, let’s make a decision on what’s best for our HVAC project. Here a some key things to consider:

Type: Is it a big commercial building or small residential area? “Galvanized steel is more suitable for commercial and industrial projects, but fabric ducting is great for residential.

Durability Requirements: If it’s durable you crave and one that won’t require continuous replacement, you can find it in galvanized steel.

Budget: On a budget, you may want flexible air conditioning ducts (or fabric ducts), which are less expensive but might need more maintenance or replacing.

Energy Efficiency: For long-lasting energy conservation, steel ducts with adequate insulation or aluminum ducts are your best bet.

Conclusion:

It is important to choose the best air duct for your HVAC project to ensure perfect performance of the air conditioning system, its durability and reasonable energy consumption. Each type of ducting—whether it is galvanized steel, fabric, flexible ducting, hose, or aluminum—has a unique set of advantages and disadvantages. For the very best in long-term performance and durability, you’ll need galvanized steel, particularly for commercial or industrial applications. Budget or residential fabric or flex ducting — is an inexpensive material that may need to be replaced regularly. In contrast, aluminium ducts are relatively inexpensive and this is also a factory-style duct that is used in the “performance” type (better flowing) variations. So, always remember to seal your duct flanges and duct work and do so on that system in — so you get the ultimate performance on the whole system and you save some energy, too. Ultimately the best ducting material for your particular HVAC project will depend on your particular need, budget and long-term plans. Speaking to HVAC pros can steer you in the right direction, and get your system up and running properly to achieve the best results.

FAQs

So which is the best duct material for your home?

Ducting & Ducting Hoses: Fabric ducting and flexi-ducting hoses are cheap and simple to install around the home.

What is the lifespan of galvanized steel ducting?

Properly taken care of galvanized steel can last for over 20 years.

Is fabric ducting energy-efficient?

Composed of fabric, these ducts offer good airflow, although they are less efficient than steel or aluminum in larger size systems.

Will my air tubes be an energy waster since they are flexible?

Flexible ducts? Can get air leakage, so they are less energy efficient if they do not get properly sealed.

How do I minimize duct leakage?

Tape or mastic joints and seal tight with good quality duct flanges.