Duct flanges are vital in HVAC systems as they ensure a breezy connection between the various sections of ductwork, thereby allowing proper flow of air. They help to keep air leaks out which in turn can diminish the systems efficiency. However, duct flanges may also encounter issues similar to other parts of an HVAC system that can impede its performance. We are among the best hvac contractors with this article discussing duct flanges, what goes wrong, and how to fix it. From duct connectors and flexible duct connectors to sealing errors, the sooner these are rectified, the sooner you can get back in business with veins of your heating or a//c system flowing smoothly and properly. Here you understand these problems so that will help to solve in time and you have a powerful HVAC system.

What is a Duct Flange?

A duct flange is a metallic or plastic part utilized in HVAC systems to connect two pieces of ductwork. This seals the ductwork itself to keep air from leaking in or out and ensures proper airflow. As with most flanges, a duct flange is simply a flat, round, or rectangular plate that has holes in it where screws or bolts are placed to help secure the sections of duct. Duct flanges are used to keep the ducts connected snugly, preventing air leaks and making sure that your heating, ventilation, and air conditioning (HVAC) system runs smoothly. They also play an important role in ensuring that the ventilation duct operates effectively. The installation and maintenance of duct flanges are closely related to the use and efficiency of the system.

Common Issues with Duct Flanges and Their Solutions

Duct flanges are important parts of HVAC systems as they help in preventing any leakage of performance air and hence make sure there is proper and complete working of the system. Nevertheless, many things can go wrong with duct flanges causing the system to perform poorly and allowing air leaks which in turn increase energy consumption. Here, we will discuss some of the most common issues with duct flanges and what you can do to alleviate them so that your HVAC system keeps running as it should. Alignment problems, corrosion, and connector issues all need to be addressed in order to keep the HVAC system operational.

Improper Duct Flange Alignment

Problem:

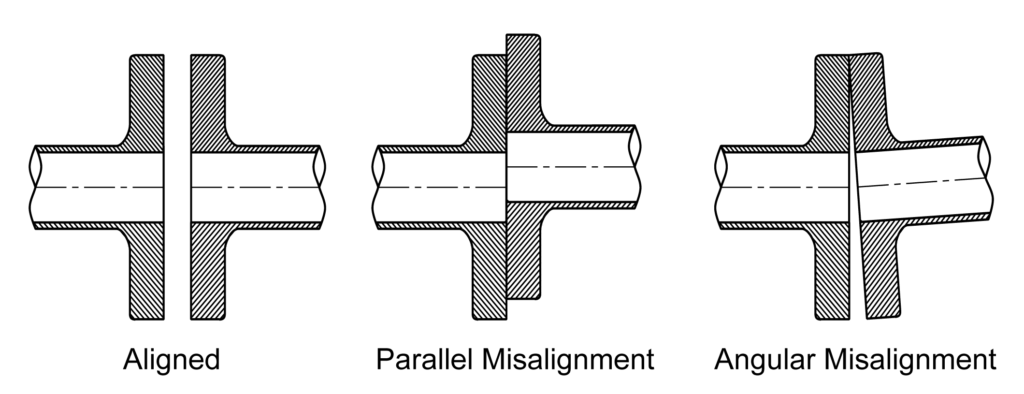

If the flanges on ducts are misaligned, there could be gaps and irregular connections between segments of ductwork which can cause air seepage as well as reduced airflow. Improperly aligned flanges will strain the entire HVAC system, leading to higher energy usage and uneven indoor temperatures.

Cause:

Improper alignment is almost like the flagship issue: rushed installs, installed poorly. It can also develop with time if the ductwork is exposed to any motion or vibrations that disrupt the location of the duct flange.

How to Fix:

To correct misalignment issues, carefully check the duct flange connections and make sure that they are fully aligned with the rest of the ductwork. If the duct flange seems not to be matched, destructure it and then put together correctly followed by a good hand-tightening of the high-grade duct connectors. So, you must test if all the corners match the right angle with the help of a level. Re-install any connectors that may have shifted or not been seated correctly.

Loose or Damaged Duct Flange Connections

Problem:

Another more common issue is that air leaks through loose or damaged duct flange connections. Poorly tightened fasteners, vibration over time or the natural wear of duct connectors can cause a loose connection.

Cause:

Loose duct flange connections occur because of wrong installation improperly installed, fastener degradation over time. This rusting or weakening of the fasteners can also be caused by environmental elements such as humidity and temperature changes.

How to Fix:

Loosen it and then, tighten all the fasteners holding the duct flange together. If the fasteners or duct connectors are worn out or damaged, replace them without delay. In the event of any damage to the flange itself, replacing the entire component is likely necessary. If you want more support, install a duct saddle support to help hold the flange connections in place reliably.

Corrosion and Rust on Duct Flanges

Problem:

Corrosion and rust are significant problems that can corrode duct flanges, which help to direct air towards where it needs to go, and the cracks result in excessive air leakage which results in an effective reduction of the system. Duct flange rust is generally related to a moisture-rich environment.

Cause:

Over time, this kind of exposure to water, air and other conditions leads to corrosion. For example, if your ducts are in areas of high humidity, such as near air conditioning units or in dark damp basements, they will be more prone to rust.

How to Fix:

If your duct flanges are rusted, wire brush the rusted areas then paint with a rust inhibitor solution. When corrosion is so advanced that the duct flange can no longer perform its function, it must be replaced. When you are replacing your parts make sure they are made with high quality rust resistant material like galvanized steel or aluminum in order to never have those rusty bits again.

Inadequate Sealing of Duct Flanges

Problem:

Poorly sealed duct flanges are among the most common sites of air leaks. Sealing: When any area of your HVAC system is not correctly sealed, it allows the energy to leave the system making it less efficient and cost more on your bills.

Cause:

Both of these materials can wear out, or the sealant application can demonstrate signs of a problem. Poor sealing may happen if the duct flange is not tightly set during installation.

How to Fix:

Examine the duct flange and junctions, if you see any splits. Use good-quality HVAC sealant to plug the openings tightly. Seal off the crossover channel where it meets the stock airbox and the duct hoses on both ends of it (you also may do this step after you have bolted it back onto our intake too) It is extremely important that you install a Duct Grill or metal HVAC duct tape here to keep cool or warm underhood air out.

Faulty Flexible Duct Connectors

Problem:

Connect the ducts to HVAC equipment such as ventilation fans & registers using duct connectors. In time, these connectors may become brittle, cracked or damaged which will result in the air leaks and reduced system output.

Cause:

Flexible duct connectors can deteriorate with exposure to UV light, temperature changes, or mechanical stress. If they are not properly installed, or if they are over-torqued, this could lead to cracking or separation from the lug nut.

How to Fix:

Check the connections on your flex-duct; look for any breaks in the material or if they are stiff. If your connectors are damaged, replace them with high-quality flexible connectors that will withstand HVAC systems. Double check that you have screwed the connectors on tightly and made sure their tightness to minimize any more leaks in the future.

Improper Support for Duct Flanges

Problem:

Improperly supported duct flanges may shift or sag with time, leading to misalignments and air leaks. This is especially crucial for larger, more substantial ductwork systems.

Cause:

Often the problem is that duct flanges were installed, but there was some necessary bracing or support simulators. Eventually, the weight of ductwork or external vibrations can shift flanges out of alignment.

How to Fix:

Place duct saddle supports at their required spacings to avoid sagging or misplacement. This friction limits the deflection and maladjustment of the connecting duct flange. Proper alignment and support of the entire system also rely on how often supports are spaced apart.

Duct Axial Fan Issues

Problem:

A Inline duct axial fan is important because it is what facilitates the movement of air through the ductwork, however problems with the fan can cause airflow disruptions thus causing lower efficiency or possibly damage to your duct flange.

Cause:

When axial fans are faulty or misaligned, this can create vibration from the fan flange side which deflects and puts stress on both the surrounding ductwork and also usually at the point of connection to the flanges. If you do not keep up the maintenance, it can cause poor airflow to the fan and also result in debris building up.

How to Fix:

Check the duct axle fan for wear and tear, dysfunction. If this has simply moved the burden onto your poor fan blades, and they are churning through a wall of dust to get air flowing as best it can, give those bastards a good clean out whilst you’re at it. If there are faults with the fan motor or blades, have them replaced before using it again.

Why Choose Airlutions for Your Duct Flange Solutions?

Airlutions is the only name you can trust to ensure your HVAC system never runs out of steam for optimal performance. We are experts at providing long-lasting, rust-proof and wear-resistant duct flanges constructed from robust materials such as galvanized duct, steel, and aluminum. Whether it’s misaligned ducts, air leaks, or failed flexible duct connectors — whatever you need fixed, we handle it cost-effectively and promptly according to your preferences. Here at Airlutions, we provide comprehensive services, from professional installations to regular maintenance, ensuring your HVAC system runs efficiently at all times. When you partner with Airlutions, you can count on exceptional service, superior quality, and energy savings for years to come. Our solutions are designed to keep your system running smoothly while saving you time, money, and energy.

Conclusion

Duct flanges play a crucial role in keeping your HVAC system in top working condition. Issues such as misalignment, loose connections, corrosion, and poor sealing can cause significant inefficiencies in your system. By addressing these problems early and seeking help from professional services like Airlutions, which specializes in duct connectors, flexible duct connectors, and duct saddle supports, you can save money, avoid expensive repairs, and extend the lifespan of your HVAC system. With proper maintenance, timely repairs, and careful installation of duct flanges using the right sealants, your system can perform as well as it did on the day it was installed. If you’re unsure about how to handle these repairs, it’s always best to contact a professional like Airlutions—after all, it’s better to get it right the first time.