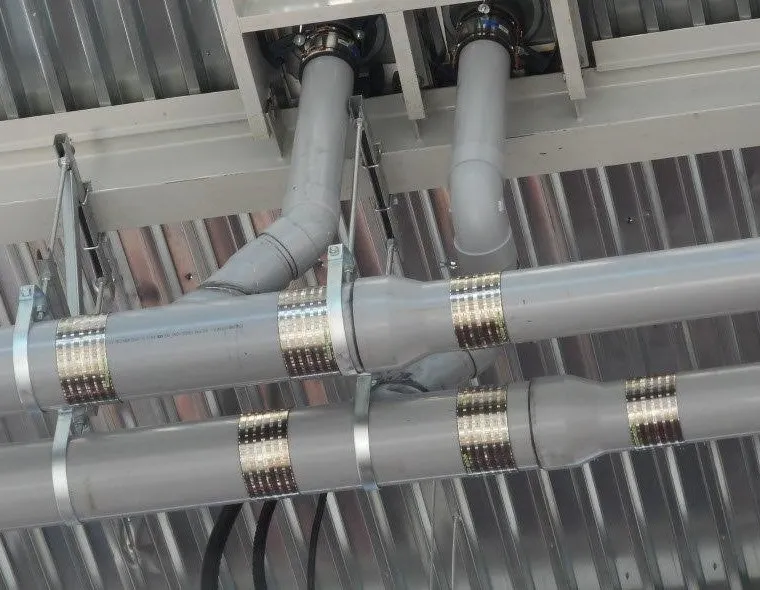

Pvc duct pipes are among the best selection options for residential and commercial ventilations because they are mechanically strong and economical. Compared with other types, the price of PVC ductwork is lower while providing lightweight and durable services that help in airflow control and HVAC system functions. This guide will showcase every detail regarding PVC duct pipes including their setup, materials used, and the significance of insulating the pipes. We will also look at the contrast of Flexible vs. rigid ducts to help aid in the decision making process on which would be best suited for your system. The worker wearing the yellow hard safety hat was repairing the water pipe line under the building with service mind.

What Are PVC Duct Pipes and Why Are They Important?

PVC duct pipes are made from durable, corrosion-resistant plastic, making them a reliable solution for ventilation and HVAC system. These PVC duct pipes offer a wide range of benefits, including resistance to chemicals, moisture, and high temperatures, making them ideal for both residential and industrial ducting systems. PVC ductwork is often chosen for its cost-effectiveness and ease of installation compared to traditional metal ducts. The popularity of PVC duct pipes continues to grow due to their longevity, lightweight nature, and the minimal maintenance required once installed.

Whether you are installing PVC duct pipes for your home or business, this material offers an efficient and durable option for all kinds of ducting needs. PVC duct pipes are made of strong and non-corrosive plastic, making them useful for Hospitality and Ventilation systems. Besides, these pipes can withstand harsh chemicals, moisture, and extreme heat. Because of these traits, they are useful for residential and industrial purposes. The cost effectiveness of PVC duct work is another reason why they are popular when compared to traditional metal ducts, along with ease of installation. The lightweight durable nature of these pipes alongside their long lifespan and the negligible amount of upkeep needed after installation boosts the popularity of these tubes. Be it for your business or home, these pipes can be relied on to be an efficient long lasting solution for all ducting requirements.

Here are some reasons why PVC duct pipes are essential:

Cost Consideration

In comparison to metal pipes, PVC duct pipes are generally cheaper, which is beneficial for both businesses and homeowners. There is also no expensive labor cost associated with PVC ductwork as this material is cost-effective.

Warranty and Repair Period

Corroding is a common wear with most duct pipes, but PVC duct pipes offer high durability and damage resistance which ensures a long lifespan. These outperform metal ducts in humid or hot weather regions as they do not rust.

Lightweight and Low Hanging Fitting

Installation of PVC duct pipes is easier because of the lower weight in comparison to metal ducting materials. Lesser downtime and labor requirement lower overall ticket cost and increased profits.

Better End Air Qualitys

With no rust or debris accumulation, PVC ductwork ensures an effective HVAC system air filtration. This is essential in residential setups as well as in commercial ventilation systems.

The Importance of Proper PVC Duct Pipe Installation

The correct Pipe insulation for proper airflow, system efficiency, and durability. Improper installation can lead to weak airflow, excessive energy consumption, and even complete system failure. Here’s how to make sure that your PVC ductwork is properly installed:

1. Measure and Plan the Layout

Take note of the entire area’s dimensions in detail before beginning anything. Having a system layout design helps reduce unnecessary moveable parts which hinder optimal airflow.

2. Prepare the Ducting Materials

For smooth installation, make certain that all ducting components are ready. This incorporates your PVC duct pipes and all related elements such as pipe connectors, elbows, and even Duct pipe installation. Using the best materials directly impacts the effectiveness of the system.

3. Cut and Fit the Pipes

Collect all the relevant materials and for the duct, cut it to standard length using either a duct saw or a pipe saw. Before securing anything, fit test the pipes to confirm that they work seamlessly together.

4. Fasten and Close the Ducts

Use appropriate adhesives and clamps to seal the joints between the PVC duct pipes. Air leaks will impact the efficiency of the entire system. Securing the Duct pipe installation ensures that they do not move during operation, providing stability.

5. Wrap Insulation Around the Pipes

Duct pipe installation on the pipes increases the efficiency of your PVC ductwork by keeping the temperature constant. The duck works more efficiently because insulation reduces heat loss, condensation, and helps minimize noise.

Choosing the Right Ducting Materials

While looking for ducting materials, one needs to take into account the cost, the place which will be the installation site, and its overall durability. Most people prefer using PVC duct pipes over other materials, but there are different options that can be taken into consideration.

PVC Ductwork Vs. Metal Ductwork

Metal Ducts

Since metal ducts made of aluminum are light, they can be moved after installation, while metal ducts made of steel are used in commercial places since their durability is very high and they can withstand high air pressures. They also have their disadvantages which are usually high cost and difficulty during installation.

Flexible Ducts

Flexible ducting is the most preferred type of ventilation in small out of reach areas. Their easy installation and added flexibility makes them a first choice, but it affects the lifespan of the ducting material itself, causing it to not last as long as the PVC duct pipes.

Why PVC Ductwork is the Best Option

When it comes to efficiency, strength, and affordability, PVC duct pipes stand out for all the right reasons. Their corrosion resistance, along with their functionality in residential and business settings, makes them incredibly versatile. Despite competitors, duct pipes made from PVC stand out for requiring lesser upkeep while ensuring high levels of airflow.

Flexible versus Rigid Ducts

The selection of flexible vs. rigid ducts is arguably the most vital decision during the installation of PVC duct pipes. Each option carries a set of pros unique to user requirements.

Flexible Ducts

Installation of Flexible vs. rigid ducts is relatively easy within reach-in, twisty, or curved spaces. Regardless, they do require less horizontal and vertical space than rigid ducts. The downside is that they are less durable and wrinkling may affect their ability to perform to the standard of Flexible vs. rigid ducts systems.

Rigid Ducts

Similar to PCV duct pipes, rigid ducts are far more durable and efficient in terms of airflow. Most of their applications are in systems that require a greater number of straight ducts. Though they are harder to install in confined areas, flexible vs. rigid ducts cannot compete with the level of performance and conservation that rigid ducts deliver.

What Is Insulation’s Role In Ductwork Pipe Insulation

Pipe insulation is vital towards achieving the ideal efficiency and durability of your PVC ductwork. Here is how:

Economical Use of Energy: insulation maintains the temperature of the air passing through the ducts and therefore uses less energy and improves system efficiency.

Mold Prevention: Prevents the moisture from condensing on the interior of the pipe which can rot or cause mold and mildew. Pipe insulation maintenance aids in maintaining steady temperatures, therefore no condensation is formed.

Quiet Modules: Improved comfort is a result of reduction of noise that is associated with the circulation of air within the duct system, as quiet modules are more efficient when incorporated into insulated ducts.

Conclusion

If you are upgrading, or installing a new system, PVC duct pipes can serve as cost effective, reliable, and durable solutions for your ventilation needs. If one understands the process of selecting the best ducting materials, duct pipe installation, and applying pipe insulation, it is guaranteed that the PVC ductwork will last long and perform efficiently. It is always a case of preference when it comes to making a choice between flexible vs. rigid ducts but there is no denying the fact that PVC duct pipes proved to be cost-effective as well as efficient. Speaking of expert advice and best pricing, Airlution remains the best in the market for PVC duct pipes.

FAQs

1. What are PVC duct pipes used for?

PVC duct pipes are used in HVAC and ventilation systems due to their durability and cost-effectiveness.

2. How do I install PVC duct pipes?

Install by measuring, cutting, connecting, and applying pipe insulation for better performance.

3. What are the benefits of PVC ductwork?

PVC ductwork is light in weight, long-lasting, budget-friendly, and helps save energy.

4. Flexible vs. rigid ducts: which is better?

Rigid ducts, like PVC, offer better performance and durability, while flexible ducts are easier to install.

5. Why is pipe insulation necessary?

Insulating pipes reduces energy loss, stops condensation, and boosts the system’s efficiency.